SEBO Australia does not manufacture, and as such the main priorities is reuse, recycle and reduce the various components that make up the SEBO vacuum cleaner for delivery in the box.

Wooden pallets are reused in the distribution system as well as supplied to other companies for use within their distribution system. Paper and cardboard is either shredded and used for packaging or recycled. Plastic including soft plastic is recycled and cartridges and batteries deposited at collection points. The paper stock used for office printing is recycled paper. Brochures, manuals and parts diagrams for servicing are available in digital format. Staff are encouraged to have a positive environmental impact across all areas at work including the collection of food scraps for composting.

Even deliveries are carefully planned to ensure our vehicles are filled to their maximum capacity and are running as economically as possible.

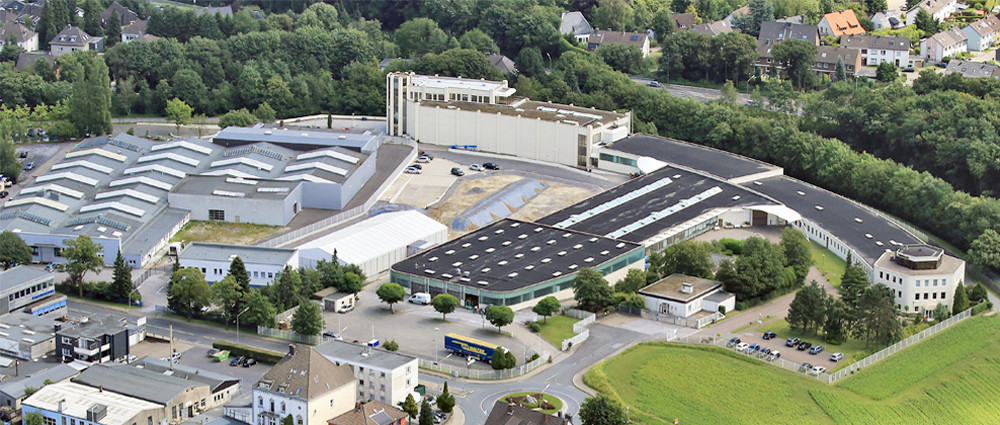

Manufactured in Germany, using locally sourced materials and components, which already ensures a smaller carbon footprint, every SEBO vacuum cleaner is made to last. This not only reduces waste and uses fewer resources, it even saves customers money. What is really impressive is the lengths the company will go to ensure every single element of a vacuum’s construction makes a minimal impact on the environment. Not only is plastic recycled into new components, but the factory is completely self-sustaining with regards to electricity – and even makes contributions to the national grid when supply exceeds demand. A combined heat and power system recovers virtually 100% of its primary energy source; as well as producing the electricity required to run machinery, the warm air created by its generator is used to heat the warehouse while engine coolant is pumped through the office radiators.

Water resources are also conserved at the SEBO factory. Rainwater (aka brown water) is collected from the roof, then filtered and stored to be used in production and within the factory washrooms, saving the unnecessary use of treated drinking water. The factory and offices are designed to use natural light as much as possible, avoiding artificial lighting and the associated power consumption and working hours are scheduled to make use of daylight hours. This also creates a much better working environment. SEBO have a highly skilled and dedicated workforce and the management of SEBO are very aware of their social responsibility and the huge contribution the commitment and health of their staff make to the quality of SEBO products.

For SEBO, reducing the carbon footprint of a product starts in the initial design process. Part of the design brief is to ensure that they will pack into the smallest possible cartons and that the carton sizes ensure that the maximum number of machines will fit onto a pallet. Most packaging is made from unbleached recycled cardboard with waste paper from the offices being shredded and re-used for packing.

Waste Electrical or Electronic Equipment (WEEE):

For recycling your end of life vacuum cleaner, the retailer who sells you a replacement machine will be able to help and advise you or contact your local council or alternatively visit www.recyclingnearyou.com.au